Why a Strapping Machine Is Critical for Reducing Shipping Damage

Why a Strapping Machine Is Critical for Reducing Shipping Damage

Blog Article

Exactly How a Strapping Equipment Can Improve Your Storage Facility Performance

In today's fast-paced warehousing environment, efficiency is essential. Strapping Machine. You might locate that automating your strapping process can considerably improve operations. With the best machine, you can reduce labor costs and reduce bundle damage throughout transportation. But not all strapping machines are developed equivalent. Understanding what to look for and how to integrate these equipments right into your existing process is crucial for maximizing their benefits. Allow's discover what makes a strapping device a necessary tool for your storehouse

The Duty of Strapping Machines in Modern Warehousing

In today's fast-paced warehousing setting, strapping makers play a crucial function in improving effectiveness and productivity. You rely upon these makers to secure packages tightly, lowering the risk of damage throughout transportation. Rather than by hand covering and strapping products, you can utilize automatic services that save time and minimize labor costs.Strapping makers assist enhance your workflow by accelerating the packing procedure. They guarantee consistency in how products are bundled, allowing you to preserve high requirements in packaging. You'll find that utilizing a strapping machine decreases the need for extra products, consequently enhancing your supply chain.Moreover, these devices are adaptable to different package shapes and sizes, making them flexible devices in your warehouse. By integrating strapping makers into your procedures, you'll not just improve effectiveness yet also create a much more well organized and effective workplace, enabling your group to focus on core jobs.

Benefits of Automating the Strapping Process

Automating the strapping process not just conserves time but likewise significantly enhances your storehouse's overall efficiency. By getting rid of manual strapping, you lower labor expenses and reduce the risk of human mistake. This means your team can concentrate on more important tasks, boosting workflow efficiency.Additionally, automated strapping devices continually apply the appropriate stress and secure packages a lot more dependably, guaranteeing that your goods are well-protected throughout transportation. You'll observe less broken items, which can bring about reduced returns and boosted customer satisfaction.Moreover, automating this procedure permits for faster throughput, meaning you can deliver more orders in much less time. This agility can provide you an one-upmanship in today's hectic market. On the whole, purchasing automated strapping improves your procedures, improves precision, and can eventually bring about greater earnings for your storehouse. Embrace this innovation and view your efficiency soar.

Key Functions to Look for in a Strapping Equipment

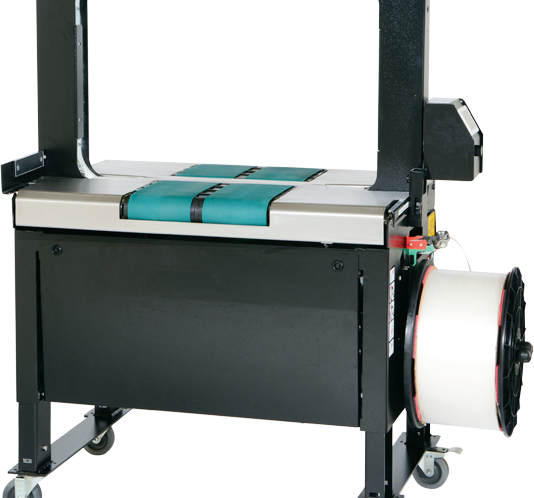

Sorts Of Strapping Machines and Their Applications

Strapping equipments been available in numerous types, each developed to satisfy details operational demands in a storage facility. As an example, semi-automatic strapping makers permit you to manually feed the band while the device does the reducing and sealing. This is perfect for reduced quantity procedures where versatility is crucial. There are totally automatic machines, perfect for high-speed atmospheres. They automatically feed, stress, and seal straps, boosting efficiency markedly.Another option is portable strapping tools, which use movement and simplicity for little jobs or limited rooms. If you handle hefty loads, think about a sturdy strapping equipment developed to deal with bigger items securely. Electric strapping devices offer regular tension for consistent results, making them a wonderful option for quality control. By comprehending the various types, you can pick the appropriate strapping maker that aligns with your storehouse's certain needs, enhancing general productivity.

Integrating Strapping Devices Into Existing Operations

Incorporating strapping makers right into your existing workflow can considerably boost and enhance procedures productivity. Begin by evaluating your existing product packaging procedure to determine traffic jams. Figure out where strapping can include value, whether it's securing boxes for delivery or bundling products for storage.Next, pick the best sort of strapping equipment that fits flawlessly right into your configuration. See to it it's compatible with your product packaging products and can handle your quantity needs. Training your team is essential; they require to recognize how to operate the machine effectively and safely.Consider putting the strapping device near packaging terminals to minimize movement. By doing this, you'll minimize time spent on product packaging tasks. Likewise, monitor the combination procedure and collect comments from your group. Adjust as needed to maximize efficiency. By attentively including pop over here strapping devices, you'll enhance your process, lower labor expenses, and inevitably enhance general storage facility effectiveness.

Instance Researches: Success Stories From Warehouses

Successful storehouses typically share tales of exactly how strapping devices transformed their operations. For circumstances, a big warehouse faced hold-ups throughout peak seasons as a result of manual strapping methods. After presenting a completely automated strapping machine, they saw a 30% boost in product packaging speed. Orders that once took hours to prepare were currently finished in minutes, enabling faster shipment and improved consumer satisfaction.Another storehouse satisfying ecommerce experienced regular item damage throughout transportation. By carrying out a strapping machine, they protected bundles better, reducing damage prices by 40%. This not just saved expenses on replacements but also improved their credibility for reliability.In both situations, the introduction of strapping makers streamlined operations and boosted performance. You can see exactly how these success stories illustrate the concrete advantages of updating your warehouse procedures. Adopting this technology might be the trick to releasing your storage facility's complete possibility.

Future Trends in Strapping Modern Technology and Storehouse Efficiency

As you look in advance, take into consideration exactly how automation and robotics are improving strapping innovation in storehouses. You're likely to see a shift in the direction of sustainable materials and wise technology that enhances performance. Embracing these fads can significantly enhance your functional performance and ecological effect.

Automation and Robotics Assimilation

Sustainable Strapping Materials

The promote higher efficiency in storehouses works together with an over at this website expanding focus on sustainability, particularly when it concerns strapping products. You can improve your procedures by selecting environmentally friendly options like biodegradable polyesters or recycled polypropylene - Strapping Machine. These products not just minimize your ecological footprint but also keep strength and reliability. By adopting sustainable strapping, you show your commitment to environment-friendly methods, which can boost your brand name image and draw in environmentally conscious customers. Several distributors are currently using innovative options that integrate resilience with sustainability, ensuring you do not give up efficiency. Shifting to these products can result in set you back financial savings also, provided their potential for lowering waste and enhancing recyclability in your supply chain

Smart Innovation Advancements

With innovations in wise technology, strapping machines are coming to be extra effective and easy to use than ever. You'll locate attributes like real-time monitoring and automated adjustments that help enhance your procedures. These machines can now integrate with storage facility monitoring systems, enabling far better supply tracking and lower mistakes. Picture having the ability to track each band's tension and quality promptly, guaranteeing peak efficiency without hands-on checks. Additionally, predictive analytics can anticipate maintenance needs, minimizing downtime. As you welcome these technologies, you'll not just enhance efficiency yet likewise boost workplace safety. Purchasing clever strapping technology is a smart option for future-proofing your warehouse and staying competitive in an ever-evolving market. Embrace the adjustment, and view your performance skyrocket!

Frequently Asked Concerns

What Is the Average Life-span of a Strapping Machine?

The typical lifespan of a strapping maker typically ranges from 5 to 10 years, depending upon use and upkeep. Regular treatment can expand its life, guaranteeing you obtain the most value from your investment.

Just How Much Upkeep Do Strapping Devices Need?

Strapping machines call for normal upkeep to ensure peak performance. You need to check components regularly, clean the machine, and change worn parts as required. Adhering to the maker's standards will assist you decrease downtime and prolong the maker's life expectancy.

Can Strapping Machines Manage Various Band Dimensions?

Yes, strapping devices can manage different band dimensions. You just require to adjust the setups or choose a maker created for adaptability. This flexibility assists you efficiently handle numerous product packaging demands in your operations.

Are Strapping Makers Energy-Efficient?

Yes, strapping equipments can be energy-efficient. They frequently use less power than manual techniques, lowering overall energy consumption. By choosing the appropriate version, you'll conserve energy and reduced expenses while keeping efficiency in your operations.

What Safety And Security Features Should Strapping Machines Include?

When picking a strapping maker, you must look for functions like emergency situation quit switches, safety guards, and automated tension changes. These improvements assist safeguard operators and maintain a secure workplace in your storehouse. You'll locate that making use of a strapping maker reduces the requirement for additional materials, therefore enhancing your supply chain.Moreover, these machines are versatile to different bundle sizes and shapes, making them versatile devices in your storage facility. When picking a strapping machine, it's important top article to take into account numerous key attributes that can substantially affect your warehouse operations. Semi-automatic strapping devices enable you to manually feed the strap while the equipment does the reducing and securing. Educating your personnel is crucial; they need to understand just how to run the device efficiently and safely.Consider putting the strapping maker close to packing stations to lessen activity. Successful storage facilities frequently share stories of exactly how strapping makers transformed their operations.

Report this page